Engineered lumber products: BENEFIT: Built to a higher level of precision providing stronger homes with straighter floors, walls & roofs. Engineered component floor systems are a combination of I-joists, AFL and/or trusses for increased strength & uncompromising floor integrity. All roof trusses are manufactured in-house for maximum quality control and integrity, strength and accuracy. Dimensional lumber is used in all structural applications, such as walls and truss components.

Gluing and nailing the OSB sub floor to your floor system helps to prevent squeaky floors. Another extra step Wardcraft takes.

We build our own trusses to assure quality. This allows quicker on-site installation as well as ensuring your trusses fit your customized home perfectly. Computer aided specialized saw allows us to make any degree of cut with precision for higher quality control when building trusses in-house.

Our Full Box Construction® joins the walls to the floor system with 7/16" exterior wall sheathing, designed to maximize the shear wall strength and structural integrity of your home (top left). Full-Box Construction also eliminates air infiltration between the walls and floor system, an area where most homes leak a tremendous amount of air. OSB sheathing is attached on the exterior of each home with low-VOC construction adhesive and heavy duty, adhesive coated construction staples (top right).

Standard 2"x6" R-23 Exterior Walls

Johns Manville Spider® Plus blown-in insulation, features interlocking fiber technology. This allows the fibers to spring and lock into cavities with no adhesive or netting. This product far outperforms fiberglass batt insulation and other blown insulation systems that introduce water into the building envelope and tend to settle over time. With Johns Manville Spider® Plus there is a much tighter installation that eliminates settling, gaps, voids and depressions forming an interlocking shield against the elements. This improves energy efficiency as well as decreasing sound transmission. The insulation is treated with an EPA registered mold inhibitor to protect against mold. In addition, only fiberglass insulation made without formaldehyde—such as Spider Fiber Plus —can pass Environmental Specification 1350, the toughest indoor air quality test in North America, with no formaldehyde detected.

Premium house wrap encases your home and creates a moisture management system. Another example of how Wardcraft goes above and beyond other builders is by caulking the OSB seams (this can be seen in top photo).

Premium house wrap encases your home and creates a moisture management system (left and center photos).

Optional Ultra Insulation R-28 walls/R-49 Attic or Optional Arctic Insulation R-32 walls/R-60 Attic

Exceed the harshest climate zone requirements in America with our standard R-23+ optional R-5 continuous rigid foam insulation for R-28 walls OR our standard R-23+ optional 9.3 continuous rigid foam insulation for a total wall R-value greater than R-32. Johns Manville AP™ Foil-Faced Foam Sheathing (photo on right) provides a continuous layer of insulation, reducing thermal bridging through wood studs, saving energy and improving comfort. Additional depth Johns Manville™ Climate Pro insulation raises the home’s attic insulation to R-60. A specialized energy truss with raised heel height at the eave allows for higher depth insulation in the hard-to-reach outside edges of a truss where most R-values are restricted by the depth of the cavity itself.

Curtain blocking is added around all windows, to easily locate a stud for hanging. Roof truses are shown in center bottom photo).

Top left: Standard 12-Gauge Wire Throughout

200-amp electrical panel ,12-guage wire and tamper resistant outlets throughout. Most builders use 14 gauge (except kitchen).

All penetrations through the exterior envelope are sealed with foam.

Windows are sealed into the rough

opening with spray foam and then flashing tape is carefully applied.

All of our wood is sanded and stained in house in their own "departments," We custom mix each of our stains to match your cabinets. As the area your wood is stained is conditioned it assures proper adhesion and finish.

Self Adhered Underlayment provides a secondary barrier to help keep water out of the home.

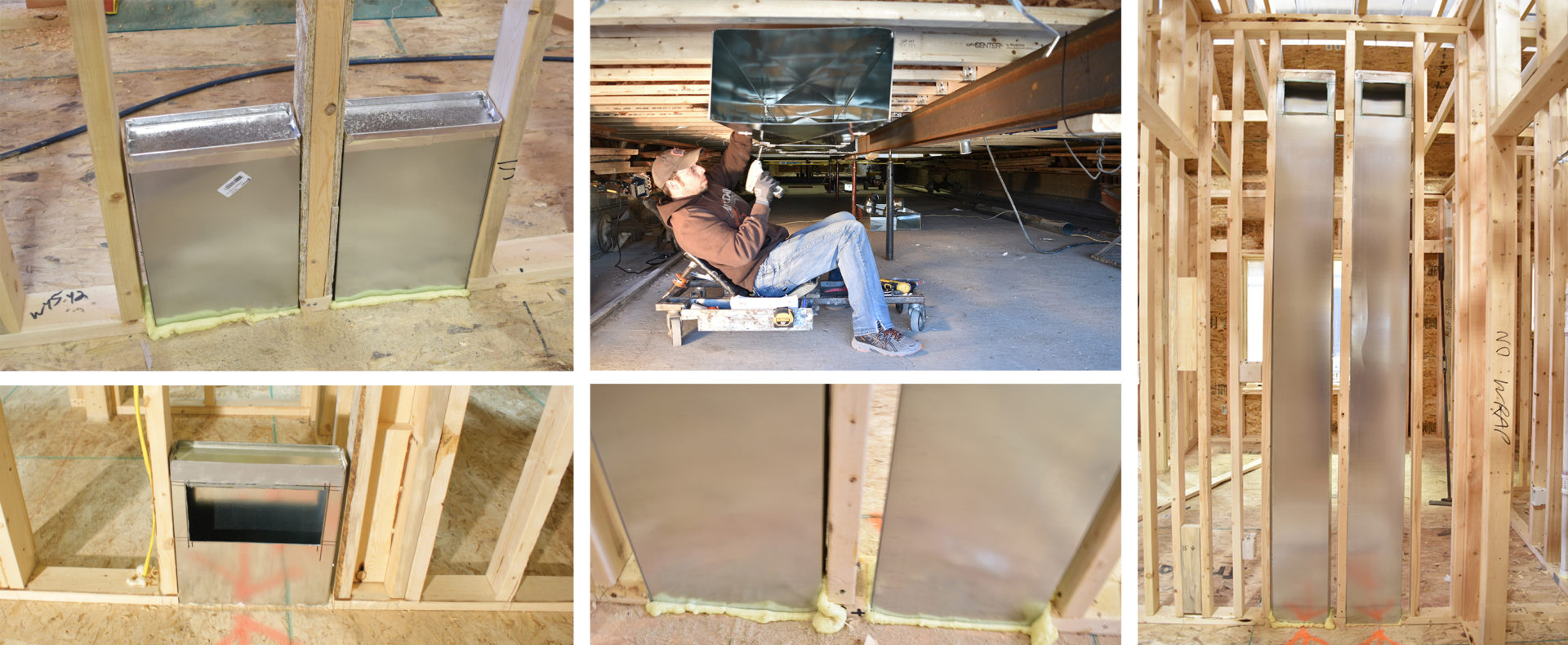

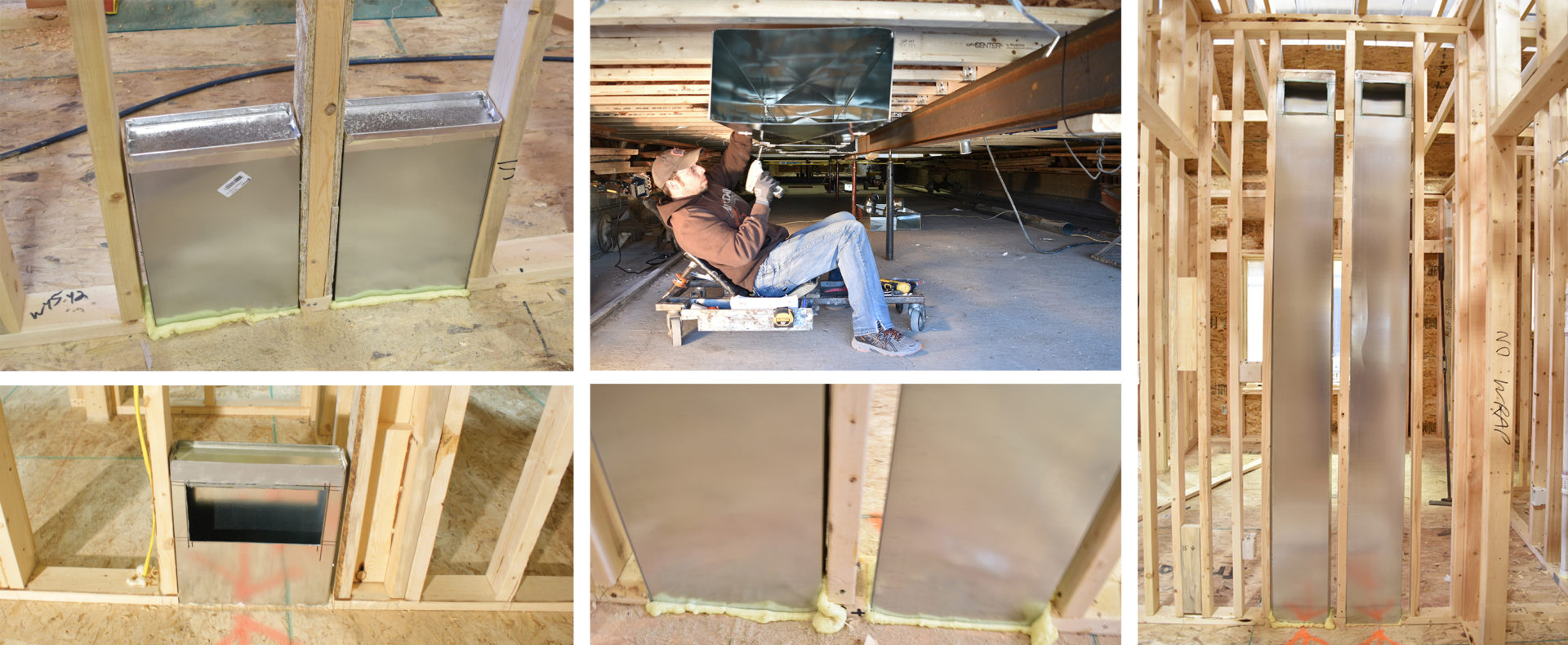

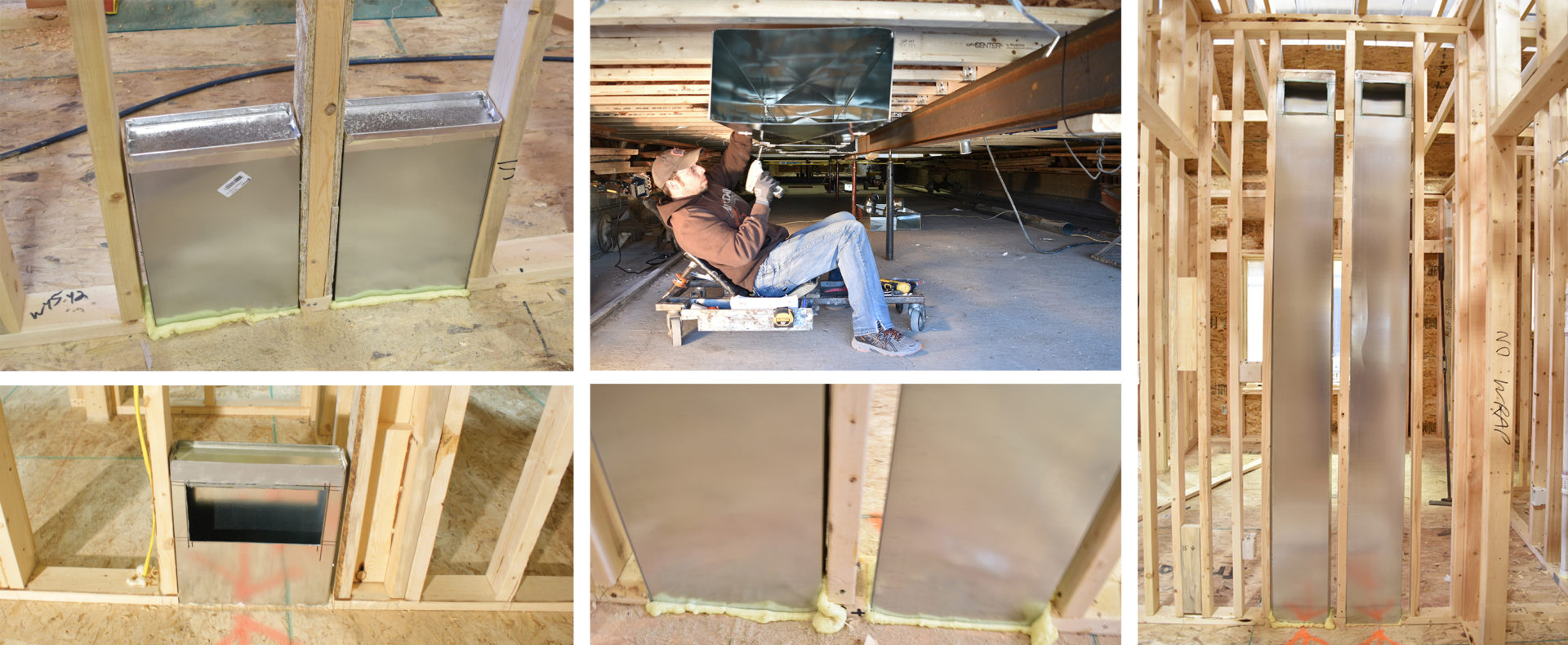

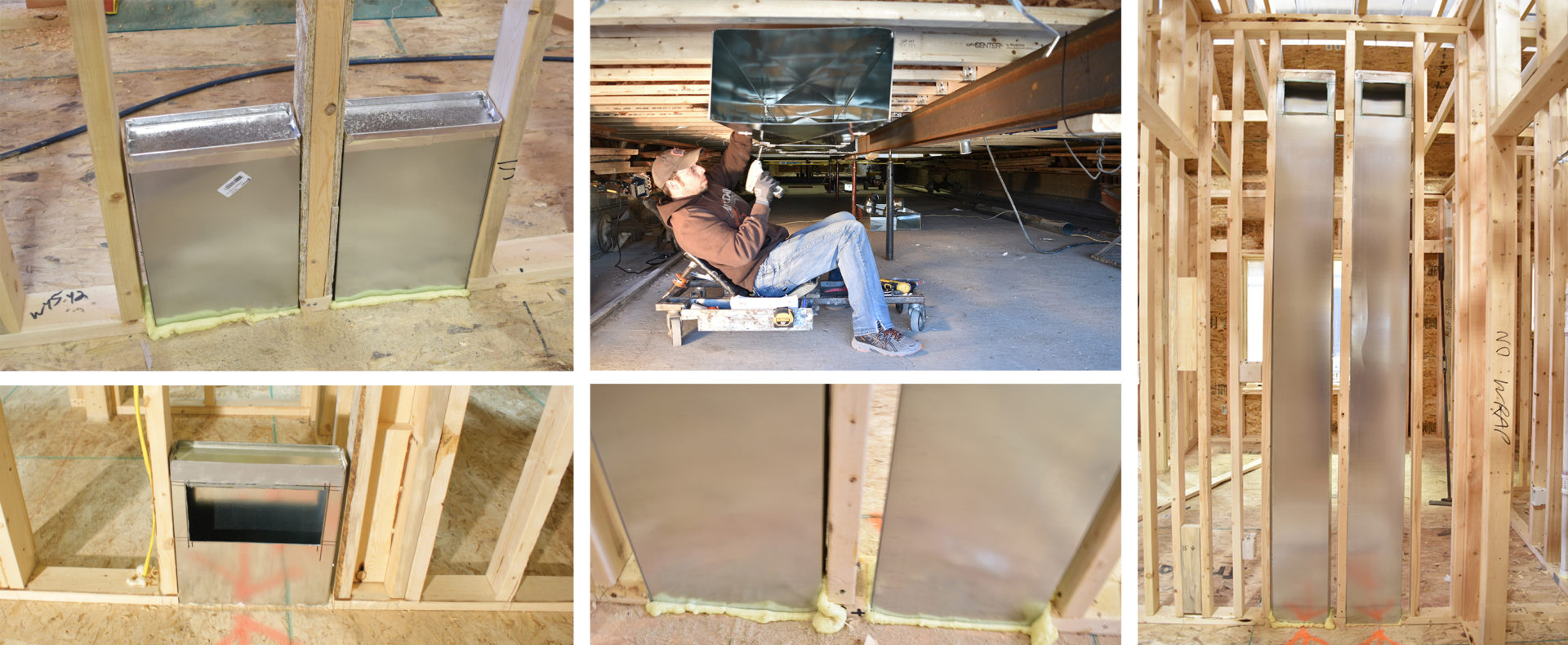

Galvanized supply and return ductwork is standard.